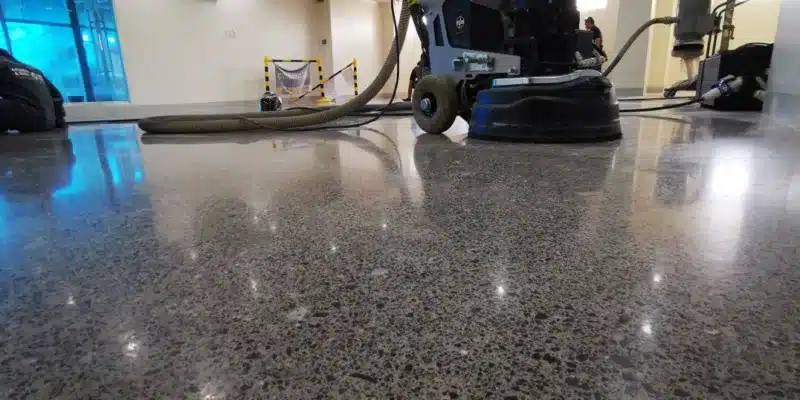

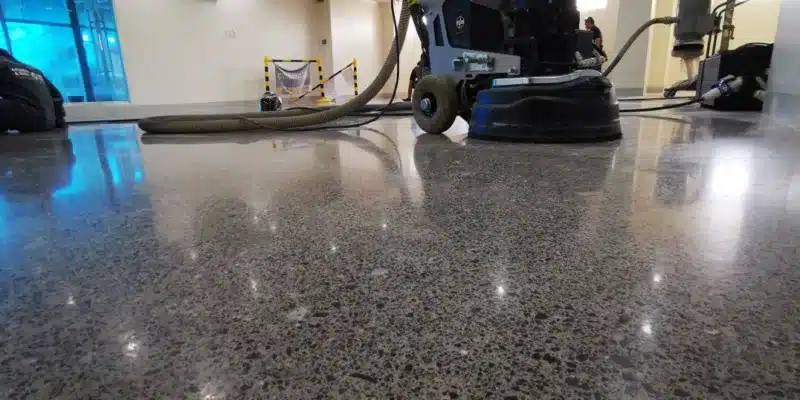

How to Polish Concrete in Perth?: Simple 5-Step Guide

With its durability, ease of maintenance, and sleek, modern aesthetic, it’s no wonder there’s a growing interest in polished concrete floors ...

Concrete core drilling is a fundamental process in many construction and renovation projects in Perth. Drilling serves as the gateway to …

Concrete grinding is a crucial step in many construction and renovation projects. Whether you’re working on a residential driveway, a commercial …

If you’re a homeowner or business owner in Perth and have a concrete sidewalk in need of repair or rejuvenation, concrete …

Concrete demolition is a complex process that requires the expertise of professionals who have the right equipment and training to do …

Concrete grinding is a process that involves removing the top surface of the concrete to expose a smoother and more even …